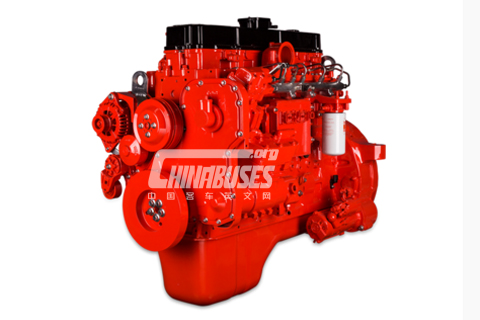

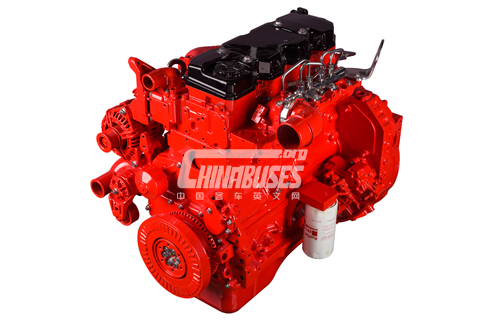

| Cummins ISL series 9.5L engines, ranging 292-385 HP, features Cummins XPI ultrahigh pressure common rail fuel system, with variable injection timing, realizing best combustion condition in all rotation and load ranges, and thus resulting in max. oil consumption reduction.With advanced design, and thus compact structure, these engines are approximately 200 kg lighter compared to the engines of same horsepower, resulting higher transportation efficiency, therefore are widely used in 12-meter luxurious tour bus applications.

Excellent power Featuring global leading Cummins ultrahigh pressure (KUNPENG) fuel injection system, max torque of these engines reaches up to 1810N.m, ensuring outstanding power output of vehicles in full load and all usage situations;Large torque at lower speed, easy startup even under full load and in soft and rough road, good gradeability, and reducing numbers of shifting, thus resulting in lower labor intensity;High power at higher speed, good acceleration and quick overtaking on the plain area and highway, thus shortening running time of trucks. First choice in saving fuel Global leading Cummins ultrahigh presure (KUNPENG) fuel injection system may reach up to 1800 Bar of injection pressure, resulting in fuel consumption reduction;Electronic control calibration software is optimized, causing normal engine operation ranges in economic zone of fuel consumption. The percentage of economic zone of fuel consumption is as high as 80%, causing engine operating in fuel saving mode most of time;Cummins EBP smart man energy saving system realizes interaction between engine, vehicle and driver, and help driver in selecting Power, Standard and Eco mode buttons according to different roads and loads, enabling engine maintaining at the optimized fuel economic zone. Reliability and durability Inheriting superior reliability from Cummins engines, integrated design and fewer component parts results in much lower engine failure rate;In view of various fuel quality, reinforeced fuel filter protection system is used, removing moisture content, ferric oxide, dust in the fuel before they entering into the fuel rail, thus reducing injector plugging, rust, wear resulting from it, therefore to maximumly reduce fuel system failures, and ensure steady engine operation. |